Frequently Asked Questions

Do you have questions about products from The Duratrac Group™? We don’t have a giant list of frequently asked questions because we’d rather have a real conversation with you. Need help figuring out which product is best for your job? Curious about installation? Please call us or send us a message.

What is the difference between Dura-Trac® SE and Dura-Trac® SB panels?

The key difference is load capacity and intended use.

Dura-Trac SE Flooring is a light-duty panel, ideal for pedestrian areas, tents, and turf protection. It features an open-web design that’s perfect for events, walkways, and lightweight structures.

Dura-Trac SB Flooring, built with our Pop-N-Lock back, is designed for heavy-duty applications such as vehicle access, equipment staging, and temporary roads. It offers greater strength and surface protection in high-traffic areas.

Not sure which one is right for your project? We’re happy to help — just ask.

How much weight can Dura-Trac® panels support?

Dura-Trac SE Flooring panels can support up to 25,000 lbs. per square foot on firm, compacted ground — ideal for pedestrian traffic, turf protection, and light-duty equipment such as carts or small lifts.

Dura-Trac SB Flooring panels are designed for heavier loads, featuring enhanced load distribution and strength, making them ideal for vehicles, forklifts, and staging heavy equipment. For demanding applications such as temporary roads or construction access, SB is your go-to solution.

Need help deciding which panel is right for your project? We’re happy to assist.

What are the dimensions and weight of each panel?

Dura-Trac Flooring panels are available in two standard sizes to accommodate different site needs:

- 4×4 feet – weighs approximately 50 lbs.

- 2×4 feet – weighs about 25 lbs. and is ideal for tighter spaces or small-scale layouts

Both panel sizes are designed for easy transport, handling, and installation by small crews.

Need help estimating how many panels your crew can handle or how they’ll ship? We’re here to help.

How quickly can Dura-Trac® Flooring be installed?

Using a crew of four, Dura-Trac® panels can be installed at a rate of up to 2,500 square feet per hour.

Recovery and removal are even faster — up to 3,500 square feet per hour — helping save time and labor costs.

Are Dura-Trac® panels durable enough for outdoor use?

Yes! Dura-Trac® panels are designed for extreme durability — resistant to corrosion, chemicals, and temperature fluctuations from -10°F to 110°F.

They are ideal for outdoor events, construction sites, and disaster response operations.

Can Dura-Trac® panels be used on natural grass and synthetic turf?

Absolutely.

Both Dura-Trac® SE and SB systems are engineered to protect natural and synthetic surfaces, minimizing compaction, turf damage, and soil erosion, while allowing airflow to preserve turf health.

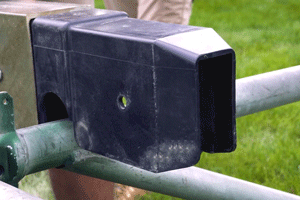

How are the panels connected during installation?

Dura-Trac® panels feature a patented slide-lock system that is self-aligning, making installation fast, secure, and seamless without special tools.

How do I clean Dura-Trac® panels after use?

Cleaning Dura-Trac Flooring panels is a quick and easy process. Use a standard pressure washer to remove dirt and debris. Avoid using harsh chemicals or high heat settings that could damage the surface.

Will the locking cams rust over time?

No.

Under normal use, the locking cams are guaranteed to remain rust-free for the life of the panel, maintaining the integrity of the flooring system.

Can I attach carpet or turf directly to the panels?

Yes, carpet or synthetic turf can be stapled directly to Dura-Trac Flooring panels without causing damage. Staples can be easily removed, and the panels self-heal, maintaining integrity and appearance over time.

Can Dura-Trac Flooring panels be cut to fit custom spaces?

Yes. Dura-Trac Flooring panels can be easily trimmed with a standard circular saw to fit around obstacles or edges. This enables precise, customized installations without compromising the structural integrity of the system. For best results, use a fine-tooth blade designed for cutting plastic, and always follow proper safety precautions.

What types of events or industries commonly use Dura-Trac® Flooring?

Dura-Trac® is used across multiple industries, including:

Can Dura-Trac® Flooring be used for heavy vehicle access?

Yes — especially the Dura-Trac® SB panels, which are specifically designed to support heavy vehicle traffic, temporary parking lots, equipment staging areas, and access roads.

Can an Atlys BEAMM be cut?

TODO: Add Answer

What is the dimension and weight of the Atlys BEAMM?

TODO: Insert Answer

Can you screw into the Atlys BEAMM?

TODO: Insert Answer